Welcome to CNC Machining Service

Kingsler offers precision CNC machining services that redefine excellence. With state-of-the-art technology and a team of skilled experts, we craft precision parts and components to meet your exact specifications.

CNC Machining Service by Kingsler: Precision in Every Detail

Kingsler is your trusted source for CNC machining services, offering expertise in crafting both simple and highly intricate components and products. Our CNC machining capabilities are among the most competitive in the industry, catering to both prototype development and large-scale production runs. We work with a diverse range of fabrication materials and provide impeccable surface finishes, serving a wide spectrum of industries including consumer goods, photo-electronics, medical, industrial equipment, military, and heavy industries.

CNC Milling: Shaping Possibilities

CNC milling is a versatile process that empowers us to create intricate shapes and surfaces for a wide variety of products. Our range of multi-axis metal CNC machine tools offers exceptional flexibility and precision, eliminating the need for mold fixation. With 3, 4, and 5 axis machines at our disposal, we can meet diverse machining requirements.

CNC Turning: Precision in Rotation

CNC turning involves the use of a rotating tool to cut material from the surface of a rod, resulting in features such as holes, flat openings, and grooves. Our advanced CNC lathes and turning centers ensure precise and high-quality machining that consistently exceeds customer expectations.

Materials & Surface Finishes for CNC Machining: Tailored to Your Needs

Kingsler offers a vast selection of materials for CNC machining, with CNC milling suitable for various shapes of raw material, while CNC turning typically utilizes rod or round-shaped materials. Here are some of our commonly used metal and plastic raw materials for rapid prototyping and low-volume production of end-use components. We also welcome customer-specified material models for machining.

- Metal: Aluminum, Stainless steel, Brass, Copper, Bronze, Carbon steel, Zinc 3#, Steel Alloy, Titanium, and more.

- Aluminum Alloy: AL6061-T6, AL7075-T6, AL5052-H32, AL6063, etc.

- Stainless Steel: 304 SS, 303 SS, 316 SS, SS 430F, 301 SS, and more.

- Hard Metals: Titanium (6Al-4V), Stainless Steels (303, 304, 316, 17-4PH), Alloy Steel (4140), Carbon Steel (1018), and more.

- Plastic: A wide range including ABS, PC, PMMA, POM (Delrin), Acrylic, NYLON, HDPE, PP, PPS, PEEK, PPO, PPE, PEI, and many others.

Our surface finish options include passivation, normal anodize, hard anodize, electroplating (PVD), powder coating, polishing, brushing, sandblasting, wooden finishes, and more.

CNC Machining Workshop: Where Precision Thrives

Kingsler boasts a well-equipped CNC machining workshop, featuring 12 sets of 5 Axis STAR and TUSGAMI Brand CNC machines, along with 16 sets of 3 and 4 Axis CNC machines. This extensive setup ensures we achieve the best tolerance levels at +/- 0.01 mm, guaranteeing exceptional precision in every project.

- 5 Axis Turn Milling Compound Machine

- STAR 5 Axis Turn Milling Compound Machine

- Turn Milling 3 & 4 Axis CNC Machine

- Raw Material (Round Shape)

- Micrometer

- STAR SB-20R Type G

Quality Control for CNC Machined Parts & Products: Precision Assurance

Our commitment to quality is underlined by our ISO9001:2015 certification. We conduct rigorous internal quality tests for our machined products, including raw material analysis, full-dimensional assessments, gauge tests, salt spray tests, surface finish evaluations, and more. Test reports are furnished based on customer requirements.

Why Choose Kingsler for CNC Machining Services?

- No Minimum Order Quantity (MOQ): We cater to projects of all sizes, from a single piece upward.

- Rapid Turnaround: Get your machined parts as quickly as 1 day.

- High Precision: We excel in machining complex parts with exceptional precision.

- Technical Expertise: Our team offers unmatched problem-solving capabilities.

- Stringent Quality Checks: We uphold strict quality checks throughout the production process, ensuring top-notch delivery quality.

- Accessible Support: Our 24/7 professional project teamwork provides continuous support from development to shipment.

Kingsler is your partner of choice for CNC machining services that meet and exceed your expectations. Contact us today to experience precision and quality at its finest.

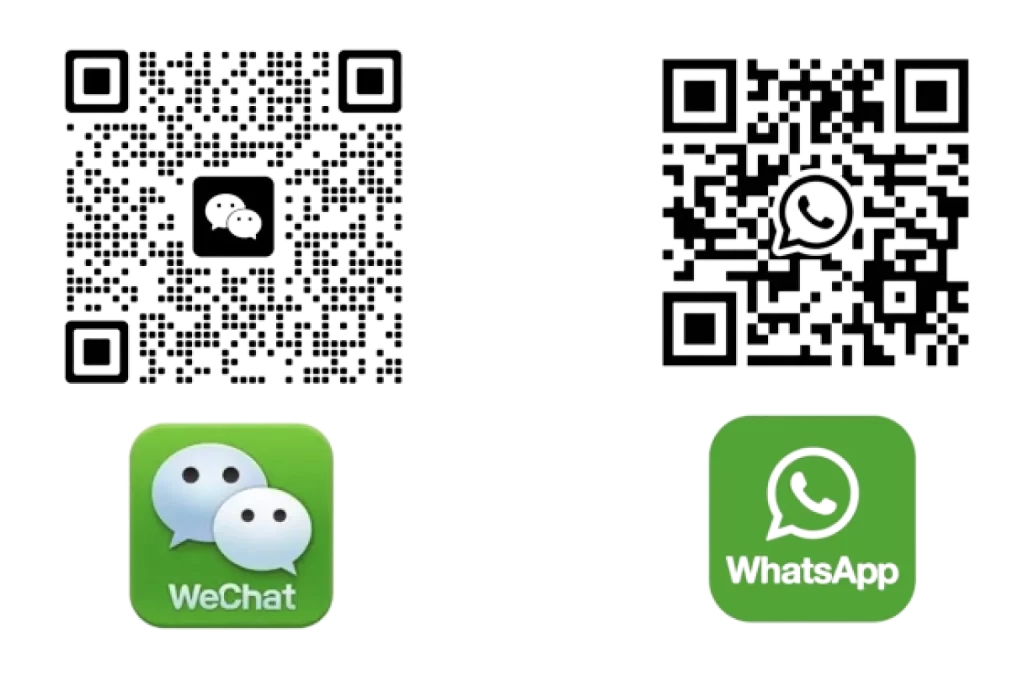

We are glad to hear from you

Any information is warmly welcome. Please do not hesitate to contact us!

- sales@kingsler.com

- + 8615867974765

-

Moday-Friday: 8:30 am - 5:00 pm

Saturday: 8:30 am - 3:00 pm -

Our Locations:

Corporate Office:

futian yinzuo 1917 Yiwu City,

Zhejiang Province China 322000 - Add our Wechat