Welcome to Plastic Injection Molding Service

Welcome to

Plastic Injection Molding Service

Kingsler’s plastic injection molding service is a top-tier solution for precision plastic part production. With state-of-the-art facilities and a commitment to quality, Kingsler specializes in transforming raw plastic materials into custom-designed components for a wide range of industries.

Injection Molding Services at Kingsler: Unlocking Possibilities

At Kingsler, we bring your ideas to life through our comprehensive injection molding services. Our extensive molding capacity, ranging from 50 to 1000 tons, empowers us to tackle a wide array of projects across diverse industries, including Consumer Goods, Home Appliances, Automotive, Medical, Electronics, Healthcare, and more. We specialize in delivering efficient solutions for the manufacturing needs of even the most intricate and precise projects, all while upholding rigorous quality control standards to ensure excellence in color, physical appearance, and tolerances. Whether your requirements call for small or large quantity production runs, we have the flexibility to meet your needs seamlessly.

Plastic Injection Molding: Transforming Innovation into Reality

Plastic injection molding is a transformative manufacturing technology. It involves injecting molten plastic materials into a mold, then cooling and shaping the material to create a part that mirrors the mold's design. This process forms the backbone of countless products across industries.

Dual-Color Injection Molding: Elevate Your Design Possibilities

Our dual-color injection molding capabilities employ advanced 2K injection molding machines. This technology allows us to inject two or even three materials (colors) simultaneously into the same mold, resulting in components that are permanently bonded together. Dual-color molding broadens your design horizons.

Overmolding & Insert Molding: Crafting Integrated Excellence

Overmolding and insert molding are sophisticated injection molding processes. They involve overlaying one material onto a second substrate part or metal insert, creating a unified component. These techniques are ideal for enhancing product performance and aesthetics.

10,000 Class Clean Room Injection Workshop: Precision Meets Purity

At Kingsler, we don't just excel in injection molding; we also produce high-quality medical products. Our 10,000-level dust-free workshop, managed by our associated company, ensures a clean and reliable environment for medical manufacturing. With 24 sets of injection equipment ranging from 50T to 450T, our clean room adheres to strict quality management and maintenance standards, including compliance with ISO 13485, BSCI, and TUV Audit.

Why Choose Kingsler for Injection Molding Services?

- No Minimum Order Quantity (MOQ): We cater to projects of all sizes, from a single piece to hundreds of thousands.

- Competitive Cost: Benefit from cost-effective solutions for both plastic injection molds and parts.

- Expertise: With extensive experience, we tackle complex and high-precision components, addressing challenges throughout development and production.

- One-Stop Turnkey Services: MaxWise offers comprehensive services, including tooling, mass production, secondary processing, assembly, and packaging, streamlining the path to market.

- Certified Production Workshops: Our production facilities adhere to ISO 9001, ISO 13485, TS16949, and TUV standards.

- Seasoned Professionals: Our team comprises engineering, quality, and production experts with over a decade of experience in the tooling and injection molding industry.

Production Facilities

Our cutting-edge facilities are equipped with over 60 machines, including:

- Plastic Injection Molding Machines: Ranging from 50T to 1000T, sourced from Taiwan, Japan, and China.

- Dual-Color Injection Machines: Ensuring vibrant and durable two-material injections.

- Silicon Injection and Compression Machines: For precise and versatile molding.

- Die-Casting and Stamping Machines: For diverse production needs.

At Kingsler, quality control is paramount, and all services are provided in-house, guaranteeing consistent quality from start to finish. Experience the Kingsler advantage and turn your visions into reality.

We are glad to hear from you

Any information is warmly welcome. Please do not hesitate to contact us!

- sales@kingsler.com

- + 8615867974765

-

Moday-Friday: 8:30 am - 5:00 pm

Saturday: 8:30 am - 3:00 pm -

Our Locations:

Corporate Office:

futian yinzuo 1917 Yiwu City,

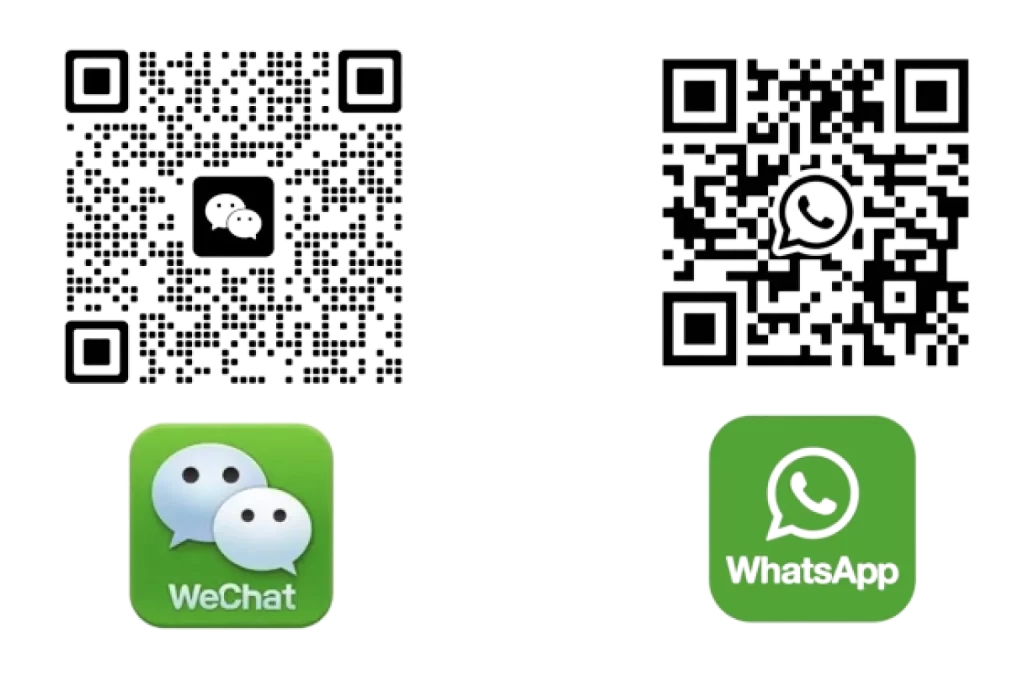

Zhejiang Province China 322000 - Add our Wechat