Welcome to Die Casting Service

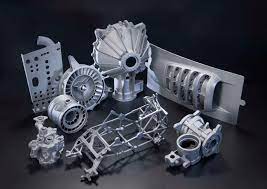

Kingsler offers a specialized die casting service that caters to the manufacturing needs of various industries. Die casting is a precise and efficient manufacturing process used to create complex, high-quality metal parts and components with exceptional durability.

Die Casting Service at Kingsler

In addition to our expertise in plastics and silicone product molding, Kingsler proudly offers professional and top-quality Zinc, Aluminum, and Magnesium Die Casting services. Whether you require sampling, low-volume production, or large-scale manufacturing, we provide a comprehensive range of services, from product design finalization to mold creation, die casting, CNC precision machining, surface treatments (including silk screen printing, pad printing, PVD, painting, and laser etching), and assembly.

Aluminum Die Casting: Excellence in Aluminum

Aluminum is a favored material for die casting, offering advantages such as high resistance to operating temperatures, lightweight properties, exceptional corrosion resistance, and ease of casting. It is extensively used in heavy industrial, automotive, and agricultural applications.

Zinc Die Casting: The Power of Zinc

Zinc's high thermal conductivity makes it an ideal choice for die casting. Its low melting point also extends the lifespan of molds, a crucial factor in its widespread use in medical equipment and facilities.

Magnesium Die Casting: Lightweight Excellence

Magnesium, a lightweight alloy, is a common choice for die casting due to its excellent EMI/RFI shielding properties, making it ideal for electrical components. It is also utilized in medical and laboratory equipment for signal protection.

Die-Casting Equipment & Facilities: Precision at Its Best

Kingsler’s independent die-casting plant boasts an impressive array of equipment, including 10 cold chamber die-casting machines ranging from 200T to 1250T, 5 hot chamber die-casting machines ranging from 88T to 3200T, over 100 precision machining tools, 80 surface treatment processing units, and manual, automatic, and electrostatic spraying lines. With our unwavering commitment to service excellence, we are fully equipped to simplify your projects.

- Die-Casting Workshop

- Manipulator Deburring Workshop

- Stamping & Shaping Workshop

- CNC Precision Machining Workshop

- Polishing & Sand Blasting Workshop

- Ultrasonic Cleaning Line

- Fully Automatic Painting Line

- Assembly Line

Quality Control for Die-Casting Products: Setting the Standard

Our dedication to quality is reflected in our ISO9001:2015 and ISO14001:2004 certifications. We conduct meticulous internal quality tests for our die-casting products, including raw material analysis, RoHS testing, full dimensional assessments, X-ray injury testing, salt spray testing, scratching tests, colorimeter checks, and fully automatic IP68 air-tightness testing. Test reports are provided as per customer demand.

Why Choose Kingsler for Die Casting Services?

- Productivity and Efficiency: Optimize your metal projects efficiently with the strong engineering support of Kingsler’s metal engineers. We offer cost-effective and secure solutions from concept to finished products.

- Collaborative Approach: We work closely with your teams to understand product design and performance requirements, reducing both time and risk.

- Technical Excellence: Our team excels in technical problem-solving and provides innovative design and fabrication solutions.

- Accessible Support: Our 24/7 professional project teamwork ensures comprehensive support from development to shipment.

- Zero Return Rates: In 2023, we achieved a remarkable zero return rate, a testament to our unwavering commitment to quality.

At Kingsler, our focus is on delivering high-quality die casting services that exceed your expectations. Contact us today to experience the Kingsler advantage for your die casting needs.

We are glad to hear from you

Any information is warmly welcome. Please do not hesitate to contact us!

- sales@kingsler.com

- + 8615867974765

-

Moday-Friday: 8:30 am - 5:00 pm

Saturday: 8:30 am - 3:00 pm -

Our Locations:

Corporate Office:

futian yinzuo 1917 Yiwu City,

Zhejiang Province China 322000 - Add our Wechat