Welcome to Silicone & Rubber Molding Service

Welcome to

Silicone & Rubber Molding Service

Kingsler specializes in silicone and rubber molding services, offering a versatile and precise solution for creating custom-made silicone and rubber components. Silicone and rubber molding is a manufacturing process that involves shaping and curing these flexible materials to produce a wide range of products with diverse applications.

Silicone & Rubber Molding Technologies at Kingsler

Kingsler’s silicone factory specializes in the conceptualization, development, and production of a wide range of silicone and rubber products. Our extensive industry experience encompasses baby care, housewares, kitchenware, cosmetics, pet supplies, sporting goods, medical devices, automotive components, and more.

Solid Silicone Molding: Crafted to Perfection

Liquid Silicone Molding: Precision in Liquid Form

Silicone Epoxy: A Fusion of Durability and Innovation

Silicone Equipment & Facilities: Tailored to Your Needs

Kingsler boasts a comprehensive array of molding equipment, including 16 sets of solid silicone compression molding machines and 6 sets of liquid silicone injection molding machines. These cutting-edge resources enable us to meet the diverse demands of our clientele, from silicone baby care products to medical components and beyond.

Custom Molded Silicone Factory: Where Ideas Take Shape

Silicone Compression Workshop: The Art of Precision Molding

Horizontal Silicone Injection Machines: Engineering Excellence in Every Injection

Vulcanizing Oven: Enhancing Durability, One Product at a Time

Custom Silicone Rubber Molding: Shaping the Future

Silicone Secondary Process: Elevating Quality and Functionality

Automatic Silicone Painting Line: Precision Meets Aesthetics

Silicone Tooling Storage: Where Precision Begins

Quality Control for Silicone Products: Commitment to Excellence

Our commitment to quality is evident through our ISO 9001:2015 and BSCI certifications. We conduct rigorous internal quality tests for our silicone products, including UV accelerated weathering testing, wear testing, tensile testing, high and low-temperature assessments, dimensional checks, and more. Our comprehensive testing capabilities extend to LFGB, FDA, RoHS VOC, and other industry standards, ensuring compliance with our customers’ specific requirements.

Why Choose Kingsler for Silicone Molding Services?

- Exceptional Service: Our unwavering commitment to service excellence sets us apart.

- Dependable Quality: Kingsler is synonymous with high-quality silicone products.

- Technical Expertise: We offer robust technical support and innovative problem-solving.

- Collaborative Approach: We work closely with our customers, gaining insights into their product design and performance needs.

- Timely Delivery: Our 24/7 professional project teamwork ensures projects are completed on schedule.

- Zero Return Rates: In 2022, we achieved a remarkable zero return rate, a testament to our commitment to quality.

We are glad to hear from you

Any information is warmly welcome. Please do not hesitate to contact us!

- sales@kingsler.com

- + 8615867974765

-

Moday-Friday: 8:30 am - 5:00 pm

Saturday: 8:30 am - 3:00 pm -

Our Locations:

Corporate Office:

futian yinzuo 1917 Yiwu City,

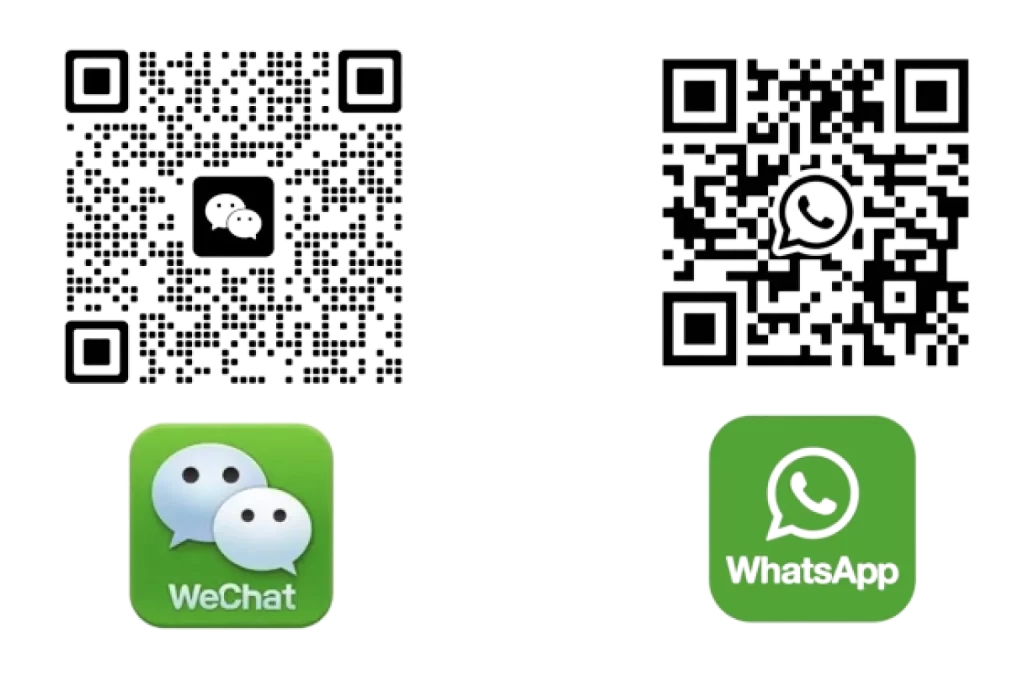

Zhejiang Province China 322000 - Add our Wechat